Company

About us

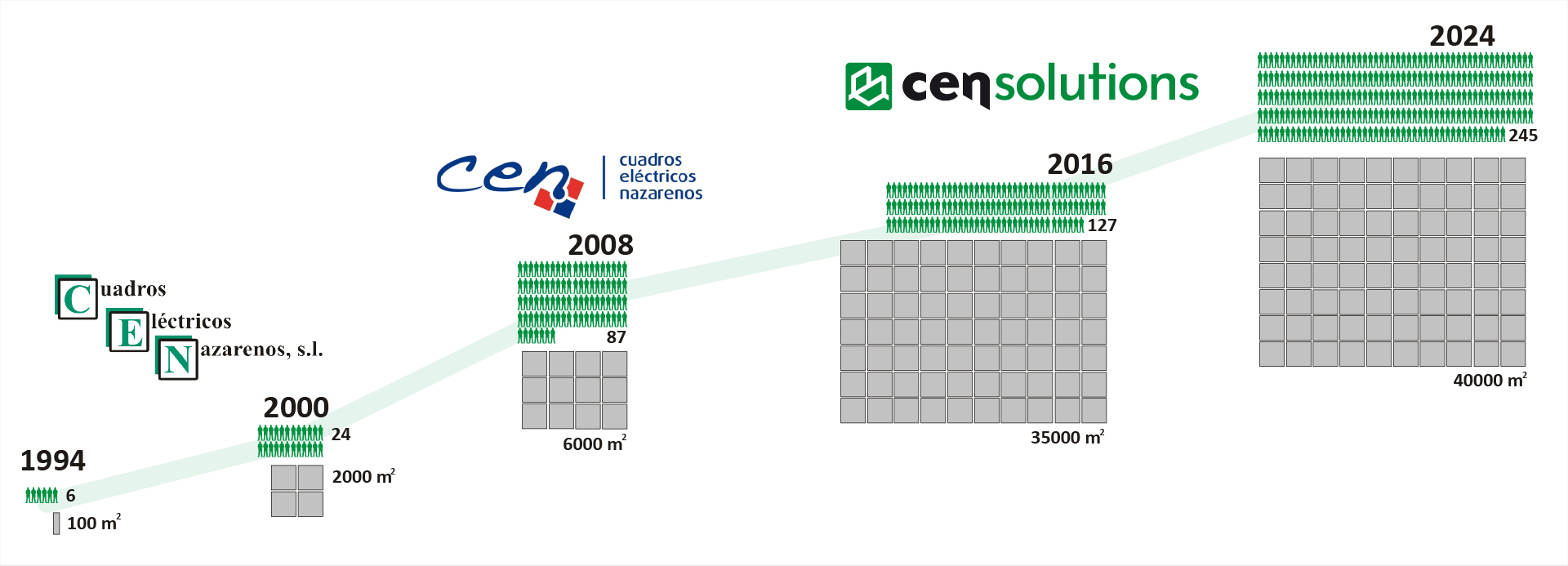

CEN Solutions is created on 1994 to provide electrical services to the industrial market, focused on design and production of electrical equipment dedicate to energy generation, Oil&Gas, industry, aeronautical and water.

Its main activity consists of the manufacture of low and medium voltage electrical equipment, modular electrical rooms, energy storage systems and equipment for all types of installations.

In addition, it offers services associated with electrical equipment such as retrofitting, modifications and preventive/corrective maintenance of existing equipment.

During its 30 years of existence, CEN Solutions has been permanently committed to knowledge as part of its business development, which allows it to be a reference in sectors such as renewable energies or nuclear fusion, while maintaining its capabilities to support decarbonization in more consolidated areas such as the petrochemical or energy generation.

Since 2020, CEN Solutions has been a leader in the supply of energy storage solutions, with more than 3.000MWh delivered and 1.300MWh under production, carried out for reference customers in the sector and in locations such as the United States, Spain and Latin America, among others.

Sustainability

Our facilities have been built according to sustainability criteria and have, among other features, their own self-consumption installation that allows us to obtain all the necessary power from renewable energy sources, or electric vehicle chargers for internal and external personnel, also collaborating in the circular economy through specific waste recycling systems.

All this progress is the result of CEN Solutions’ commitment to sustainability and the minimization of the carbon and hydric footprint on the equipment produced.

History

1994

Creation of the company

Cuadros Eléctricos Nazarenos, S.L. was founded in 1994 in Seville as a manufacturer of electrical panels. The company is founded by two partners with the rental of its first commercial premises of 200 square meters located in Aragón Street Nº54 in Dos Hermanas (Seville).

1996

Relocation

Due to the increasing volume of work, they are soon forced to rent a 400 m2 warehouse and later another one of 800 m2, both in 19 de abril street in Dos Hermanas. During this period the company has a maximum of 10 employees.

2000

The company acquires land and builds new facilities in Avenida de Sevilla in Dos Hermanas (Seville).

The capacity is doubled to face new clients in energy and oil & gas.

2006

The number of 85 employees is reached in 2006,

and an exclusive distribution agreement is signed with the Danish company Elsteel, manufacturers of modular systems at international level, through which CEN Solutions becomes the only authorized distributor of the Elsteel modular system in Spain. The number of employees reached 85 in 2006.

2009

New facilities in P.I. La Isla

A new production center is established in La Isla (Seville) with larger dimensions: 6,100 m2 of land with 4,000 square meters of warehouse and offices. This acquisition increases the company’s production capacity, allowing it to take on larger projects, increase hiring and increase the workforce to a total of 90 employees. This is considered a qualitative and quantitative leap for the company, initiating larger projects in the water and renewable sector.

2013

Maintenance contract with Airbus, EADS

CEN Solutions starts new business lines such as electromechanical preventive and corrective maintenance. For this reason, it signs a contract with Airbus Military, for which it assigns a staff of 40 operators to carry out maintenance work on tooling and machinery at the Airbus A-400M production plants in Seville and Getafe.

2016

Purchase of the manufacturing division of Inabensa, S.A. and relocation to Torrecuellar, with a further increase in size and the acquisition of new capacities for the international market and the energy transition.

CEN Solutions acquires the production plant of Inabensa belonging to the Abengoa Group in Seville. From there, CEN Solutions was created as a commercial brand symbolizing the union of two production centers of reference in Spain and facing the manufacture of equipment for the national and international market and expert maintenance activities and associated facilities. This involves the incorporation of the designs, approvals and references of the activity assigned to the capabilities of this center, as well as the acquisition of the know-how related to the manufacturing business activity. This complements the original activities of the industrial market with those acquired for energy and Oil&Gas. CEN Solutions is heading into the future with a new slogan: Smart Energy Solutions.

2019

Business consolidation

During the last few years, CEN Solutions has been recognized for its business trajectory by being awarded the SME of the Year 2019 prize in Seville by the Chamber of Commerce, which recognizes the work of the company as a generator of wealth and creator of employment in the performance of its work. In addition, it has recently been selected by the Spanish Confederation of Small and Medium Enterprises (CEPYME) as CEPYME500 Company in 2020, a project that identifies, selects and promotes the set of 500 companies that lead the country’s business growth, both for their results obtained in recent years and for their capacity to generate activity and employment, innovation potential and international projection.

2022

Relocation to Megapark

We are facing a new stage of growth with the inauguration of new facilities that are better adapted for the production of electrical rooms and that also include new segregated workplaces for mechanical production, a dedicated laboratory for electrical load testing with a power of 2x2MW, overhead cranes in 3 of the four warehouses, among others.

These new facilities allow us to be prepared to continue supporting our customers in the power generation, Oil&Gas and industrial sectors in their actions for decarbonization and energy transition.

Corporate Purpose and Values

Our values

Responsibility

Act responsibly and build relationships based on ethics, integrity, sustainable development, respect for human rights and the communities affected by the company’s activities.

Integrity, transparency and honesty

Act with the highest standards of business conduct and professionalism, sharing truthful, relevant, complete, clear and useful information.

Knowledge and innovation

Apply creative ideas that allow us to continuously improve, providing sustainable and differential solutions to create value for our customers.

Security

Promote a global culture prioritizing safety in all areas of our business activity.

Our purpose

“ Providing innovative technological solutions for sustainable development ”

Quality Management Systems

CEN Solutions has implemented and maintains a quality management system as a means of ensuring the conformity of its products and services with the requirements specified by its customers, involving all areas of the company and interested parties.

CEN Solutions’ quality system is structured to comply with ISO 9001 “Quality Systems – Requirements” and ISO 14001 “Environmental Management System – Requirements”.

Quality System for Nuclear Power Plants

Facilities

Megapark Business Park

In order to answer to our growth in recent years and to serve our customers, we have new facilities in the Megapark Business Park in Dos Hermanas. With a total of 46,000 m2, we are one of the largest industrial facilities in Spain dedicated to the manufacture of electrical equipment. This move has meant an increase in our productive and technological capabilities, an exponential growth and the generation of qualified employment.

This step forward currently makes us one of the few companies in the sector with the capacity to develop the complete product cycle and actively participate in the energy transition:

All these engineering and production capabilities, within a context in which the need for localized production in Europe has been detected, has allowed us to be prepared for a new stage of the company that we started with the move to the new facilities in Megapark Dos Hermanas, where we have significantly increased the production capacity associated also with a generation of qualified and high value employment, and that will allow us to face new challenges in the near future.

From the operational point of view, the new facilities provide capacity and greater efficiency in the production processes for which automated means and digitalization of the processes have been taken into account. To this end, the new facilities have been built to handle the large volumes and weights required for the development and manufacture of plug&play electrical buildings, energy storage systems, photovoltaic converters and inverters, medium and low voltage electrical panels and transformer stations.

The move to these facilities represents a capacity increase of more than 50%, both in terms of surface area and production capacity, and allows to strengthen even more CEN Solutions’ leadership position in the energy transition.

In addition to modern offices of 2,800 m2, there is a covered manufacturing area of 18,000 m2 with specific production lines for energy storage systems and converters, clean rooms for electronics, automated mechanical and electrical manufacturing equipment, collaborative robots and a test bench with a capacity of up to 4 MW.